Unpacking CAN XL: Features That Outclass Legacy Protocols

CAN XL rearchitects the CAN protocol to meet the bandwidth, flexibility, and real-time demands of software-defined vehicles. Positioned between CAN FD and Ethernet, it is purpose-built for scalable, high-performance in-vehicle The following are five key innovations that make CAN XL a leap forward in automotive networking:

- Flexible Frame Structure for Optimized Latency and Throughput

- Dual Bit Stuffing for Reliable High-Speed Synchronization

- Work Alongside with CAN FD and Classic CAN

- Enhanced Error Handling

- Ethernet Tunnelling and Native IP Support

We unpack each of these innovations in the sections that follow.

1. Flexible Frame Structure for Optimized Latency and Throughput

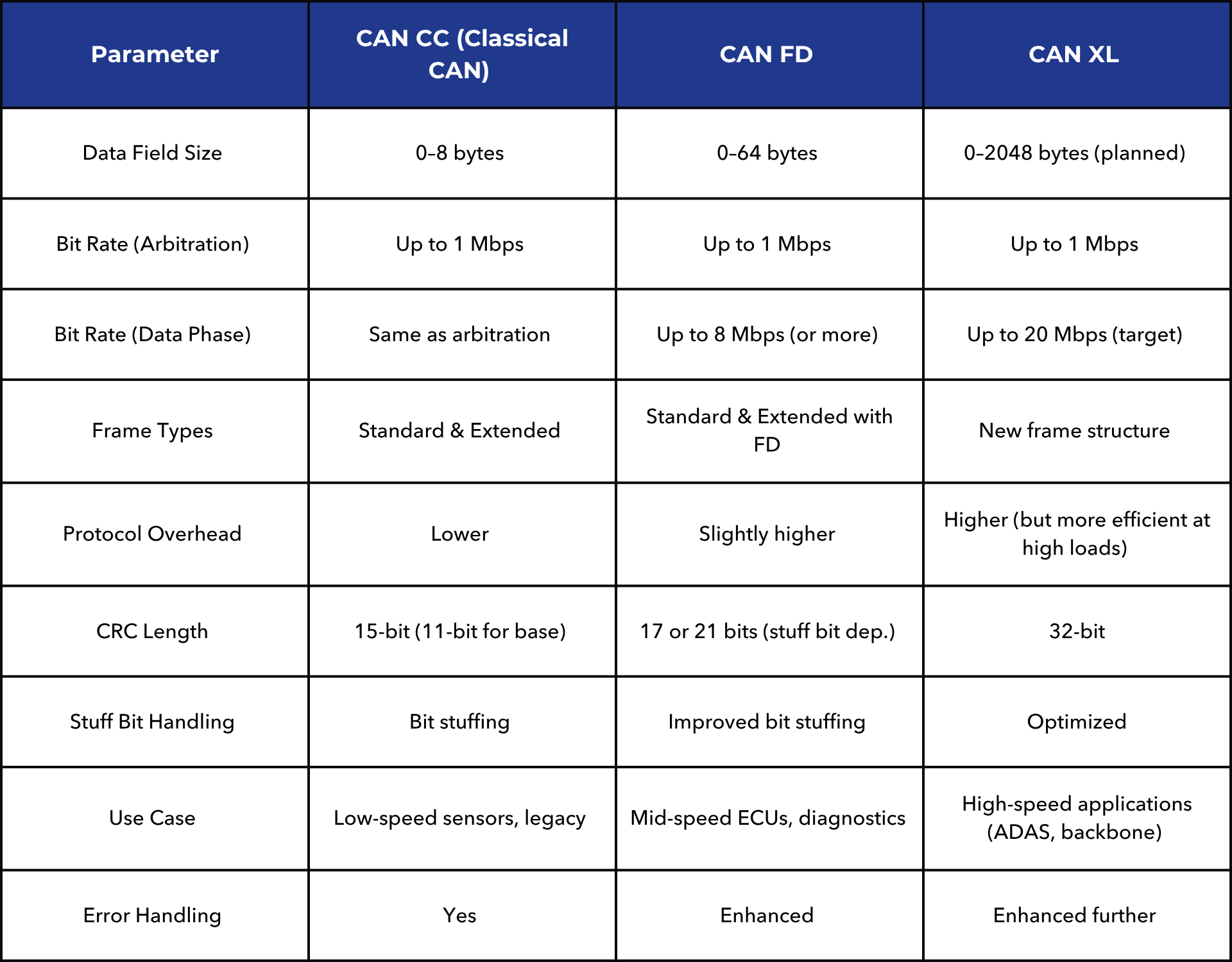

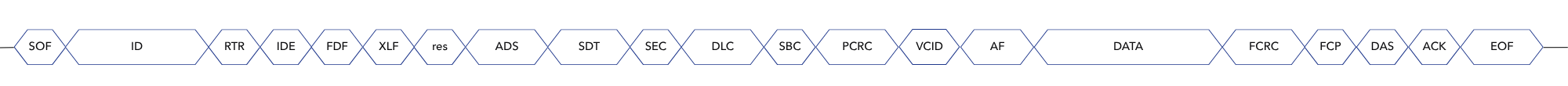

Simplified Representation of CAN XLs Frame Structure

Simplified Representation of CAN XLs Frame Structure

CAN XL introduces a flexible frame architecture that significantly enhances how data is prioritized, structured, and transmitted. Unlike traditional CAN protocols, CAN XL decouples the arbitration and data transmission phases. By separating arbitration and data transmission into two distinct phases, CAN XL ensures more predictable timing. For instance, control messages no longer compete with large data frames for bus access — reducing latency and improving overall network responsiveness. As a result, CAN XL can handle complex data exchanges and multiplex multiple protocol types within the same network.

Additionally, the data phase transmission header includes fields that support features like VLAN (Virtual Local Area Network) tagging and flexible payload handling. Together, these capabilities provide granular control over how data is routed, prioritized, and processed. And because of this flexibility, the CAN XL protocol becomes valuable, especially in mixed networks where both low-latency control systems (like braking and steering) and high-bandwidth data (like RADAR and LIDAR) applications coexist.

2. Dual Bit Stuffing for Reliable High-Speed Synchronization

To ensure precise synchronization at elevated bitrates, CAN XL introduces a dual-bit stuffing mechanism that refines the traditional approach used in Classic CAN.

- Dynamic Bit Stuffing (Arbitration Phase):

Similar to Classic CAN, a stuff bit is inserted after 5 identical bits. This avoids long bit sequences, preventing desynchronization or bit-level errors and preserving data integrity during arbitration. In simple terms, a stuff bit is an extra “filler” bit automatically added to break up long runs of identical bits so the receiver can keep in sync.

- Fixed Bit Stuffing (Data Phase):

Fixed bit stuffing is used during the data phase, where a stuff bit is inserted after every 11 bits of data. This regular pattern is essential for ensuring signal integrity and timing accuracy at high data rates (up to 20 Mbps), improving synchronization and reducing complexity compared to traditional dynamic stuffing methods.

For engineers designing ECUs, this distinction isn’t just theoretical—it directly impacts hardware implementation. Fixed stuffing introduces predictable, consistent intervals, which simplify receiver design and reduce the computational load on synchronization logic. Dynamic stuffing, on the other hand, requires real-time bitstream analysis. Together, these two stuffing methods enhance bit-level robustness, ensuring that receivers maintain synchronization throughout both arbitration and data transmission. This is particularly critical for modern high-bandwidth automotive applications, such as ADAS, gateways, and backbone networks, where precise timing and data integrity are essential.

3. Work Alongside CAN FD and Classic CAN

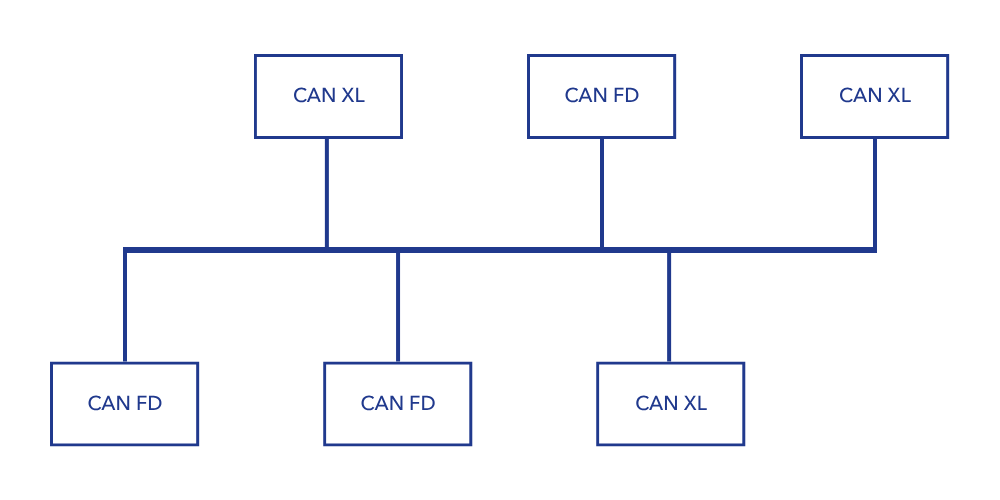

Integrated CAN XL and CAN FD nodes communicating over a shared bus demonstrating flexible communication

Integrated CAN XL and CAN FD nodes communicating over a shared bus demonstrating flexible communication

One of CAN XL’s standout features is its ability to operate in mixed-mode networks, coexisting smoothly with both CAN FD and Classic CAN nodes on the same physical bus. This backward compatibility ensures that legacy systems remain functional even as new, high-performance capabilities are introduced.

Key enablers of this seamless integration include:

- The XLF (eXtended Length Format) field in the arbitration phase signals whether the frame is CAN FD or CAN XL. As a result, legacy CAN nodes can detect a CAN XL frame early and switch to a passive state, avoiding any attempt to process a frame they do not support.

- CAN XL frames use a unique format and specific bit patterns that are not recognized by Classical CAN or CAN FD nodes. This causes legacy nodes to remain passive during CAN XL transmissions, maintaining bus integrity in mixed networks.

- CAN XL includes a Frame Format Type (FFT) field, allowing all nodes to distinguish between Classical CAN, CAN FD, and CAN XL frames. This capability ensures proper frame handling and prevents data loss in mixed-protocol environments.

These innovations enable the seamless integration of CAN XL nodes into existing bus with minimal adjustments.

4. Enhanced Error Handling

CAN XL introduces a robust error-handling architecture tailored for high-speed, high-volume automotive communication. A key innovation is the use of two separate 32-bit Cyclic Redundancy Check (CRC) fields:

- Frame CRC (FCRC): Validates the integrity of the entire frame, including headers and control information.

- Payload CRC (PCRC): Specifically protects the payload data.

This dual-CRC approach allows systems to precisely localize errors, distinguishing between control-level and data-level faults. Such separation enhances diagnostic granularity and supports more intelligent error recovery strategies. For example, if only the payload is compromised, the system may opt to retransmit just the data segment or log the incident without discarding the entire frame. This selective handling reduces latency and improves overall network efficiency.

Given CAN XL’s large payload capacity (up to 2048 bytes) and 20 Mbps data rates, these enhancements are vital for maintaining reliability in next-generation automotive and industrial networks.

5. Ethernet Tunnelling and Native IP Support

CAN XL marks a significant evolution in automotive networking by enabling Ethernet tunnelling and IP packet transport, a first for the CAN protocol family. This tunnelling capability allows encapsulation of Ethernet frames within CAN XL frames, bridging traditional CAN networks with modern IP-based communication systems.

Due to its large payload capacity and flexible frame structure, it enables encapsulation and fragmentation of Ethernet frames and TCP/IP packets across multiple messages. For example, a large IP packet can be fragmented across multiple CAN XL frames using sequence counters and protocol identifiers. On the receiving end, these fragments are reassembled to restore the full message — enabling real-time, end-to-end communication over a traditionally non-Ethernet medium. Fields like Protocol Type and Sequence Counter ensure accurate reassembly, delivering reliable end-to-end IP communication over the CAN bus.

This capability bridges conventional in-vehicle networks with modern IP-based systems, enabling seamless communication between ECUs and cloud platforms. With native support for high-level protocols like HTTP (Hypertext Transfer Protocol), MQTT (Message Queuing Telemetry Transport), and WebSocket, CAN XL opens the door to direct integration of cloud -based services, over-the-air updates, real-time diagnostics, and advanced telemetry.

Simplified Representation of CAN XLs Frame Structure

Simplified Representation of CAN XLs Frame Structure

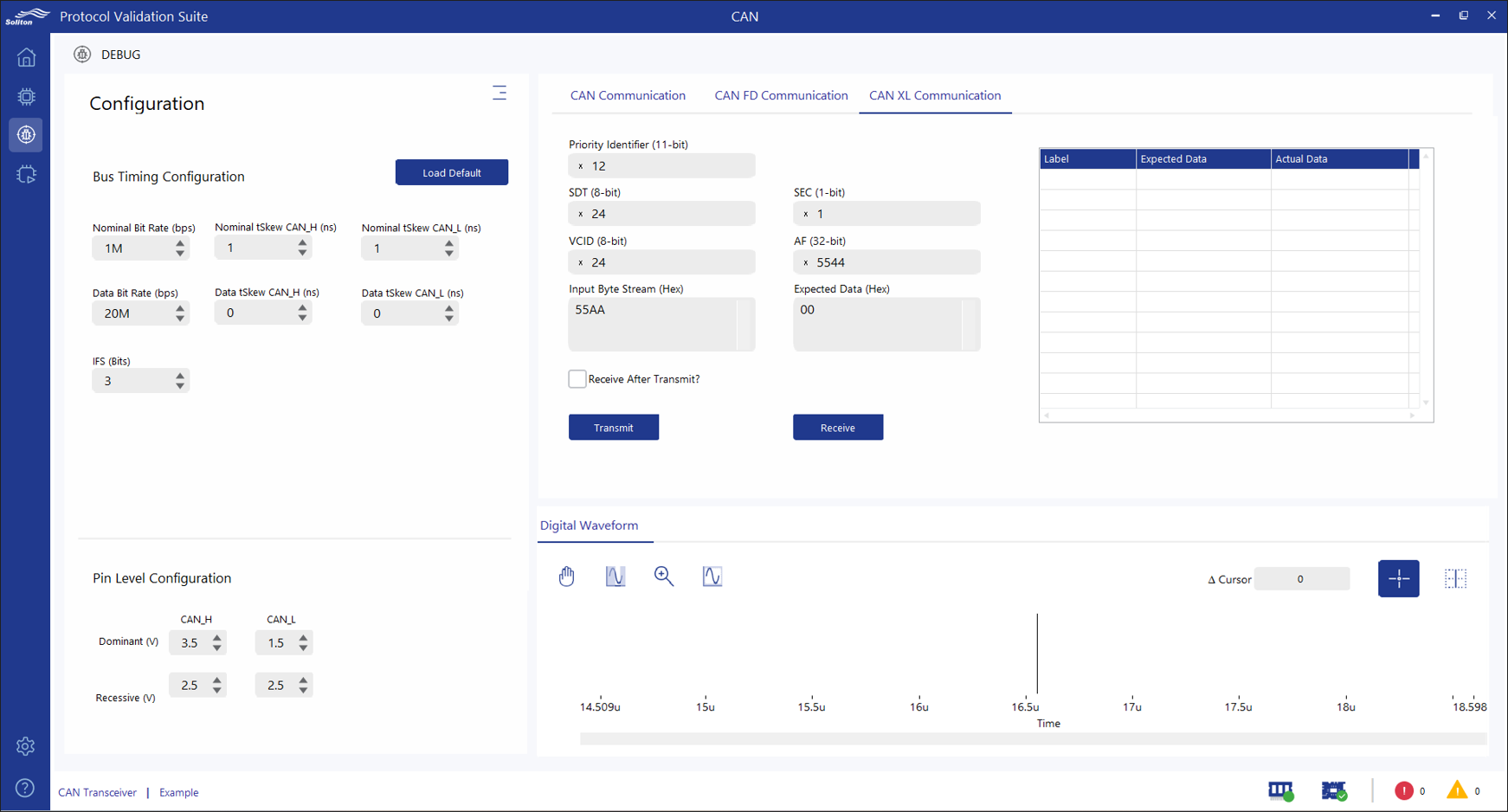

Soliton’s PVS CAN XL Protocol Validation Tool

Soliton’s PVS CAN XL Protocol Validation Tool