The Need for Automation and Software Infrastructure

Today’s production environments incorporate automated test equipment (ATEs) from industry leaders such as Chroma, Advantest, and NI-STS that can automate and execute a wide range of tests with speed and precision. While advanced ATEs have significantly improved testing, production teams still encounter operational inefficiencies across workflows such as:

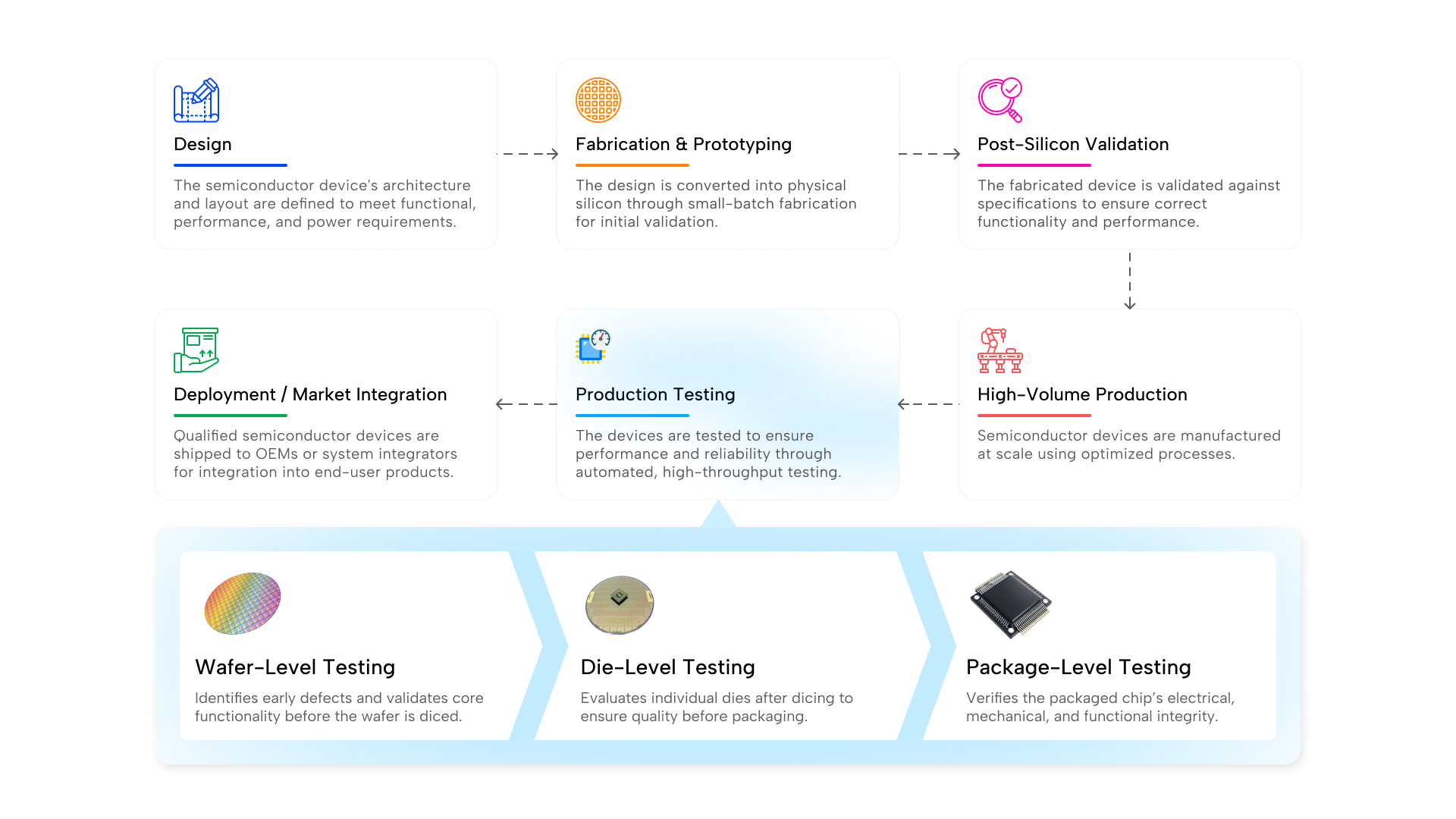

- Manual orchestration across test stages: Engineers must independently coordinate testing across wafer, die, and package levels, often relying on custom scripts and manual setup replication.

- Inconsistent procedures and redundant scripting: The absence of standardization across teams and ATE platforms results in variability in test quality and repeated effort in developing similar test logic for different stages or tools.

- Disjointed data flows: Test data is isolated at each stage, making cross-stage correlation, early anomaly detection, and root cause analysis difficult. This hinders coordination and real-time visibility across the workflow.

To bridge these disparities, semiconductor manufacturing requires more than just automation at the hardware level. It requires a comprehensive software infrastructure that ties everything together by standardizing test execution, centralizing control, enabling data-driven insights, and unifying operations across all stages of testing.

How Automation and Software Infrastructure are Reshaping Semiconductor Manufacturing

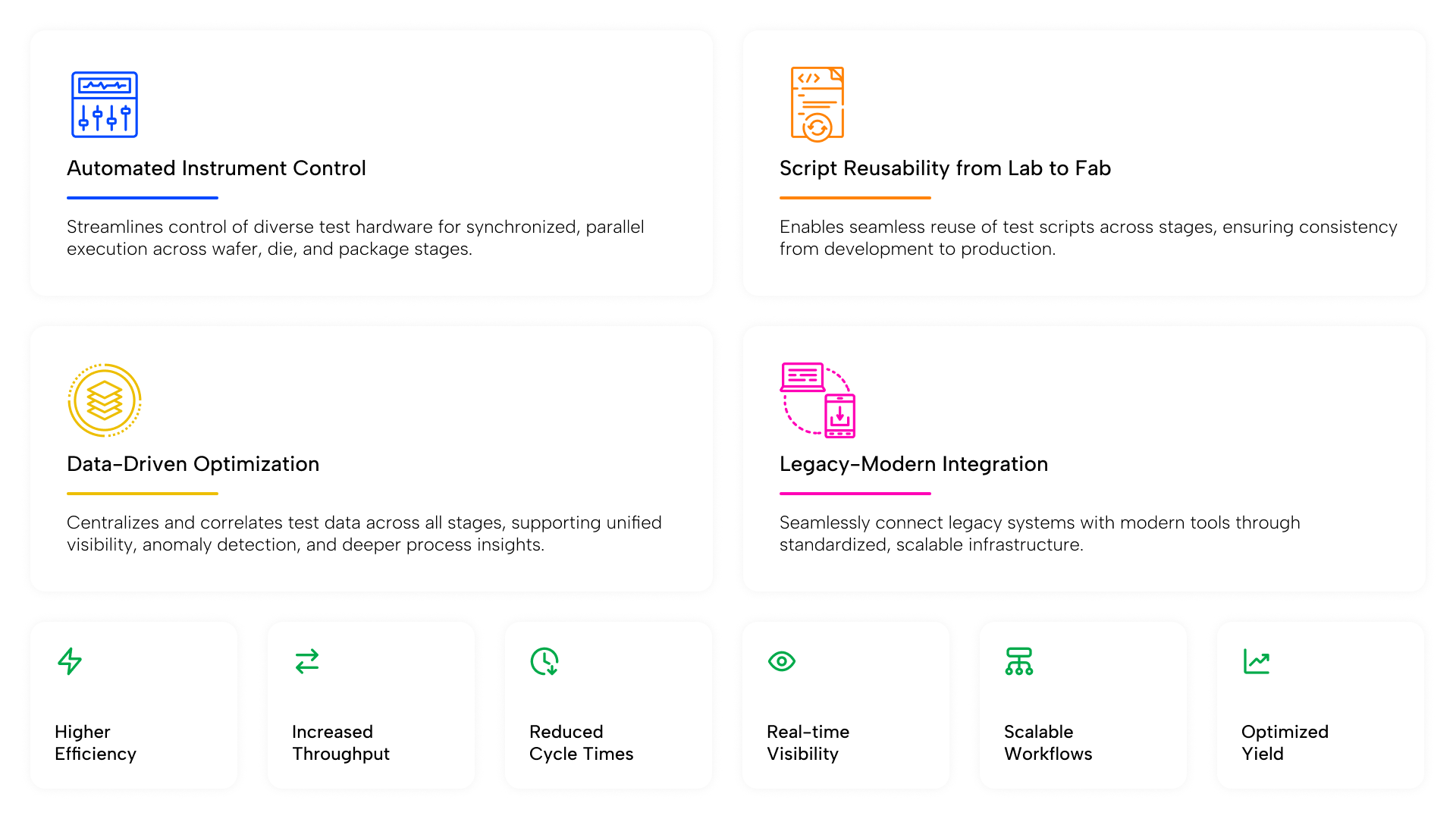

The integration of a comprehensive software infrastructure and automation brings transformative impacts to semiconductor manufacturing:

- Increased Throughput & Reduced Cycle Times

Automation and robust software infrastructure eliminate manual intervention by orchestrating test setups, automating instrument control, and aggregating real-time test data throughout production. Parallel execution of multiple test routines and intelligent scheduling optimize equipment utilization, enabling faster validation of thousands of chips per hour while maintaining precision.

- Enhanced Quality & Consistency

Standardized test execution and centralized control ensure that every device is evaluated under uniform conditions, minimizing human error and setup variations. Automated test sequences run predefined conditions with real-time anomaly detection, reducing defect rates and enhancing long-term reliability so that every batch meets the highest performance standards.

- Expanded Test Coverage & Script Reusability

With a unified automation framework, test scripts created in one stage can be reused in another. For example, test scripts developed during bench validation can be seamlessly reused in high-volume production. This eliminates redundant scripting across stages and platforms, ensuring methodological consistency and standardization from lab to fab and significantly reducing engineering effort.

As part of a Lab-to-Fab initiative with Analog Devices Inc., we enabled enterprise-wide standardization in semiconductor validation and characterization. The infrastructure bridged bench validation and high-volume production, with reusable test scripts driving a 30% efficiency boost in the overall process.

Learn more about our partnership and the impacts we created.

- Data-Driven Process Optimization

Centralized data collection and correlation across stages unlock actionable insights, enabling engineers to detect yield fluctuations, process drifts, and equipment inefficiencies in real-time. AI-powered analytics further enhance this by identifying failure patterns and predicting potential defects, enabling proactive, yield-improving interventions.

- Bridging the Gap Between Legacy and Modern Systems

Integrating legacy systems with modern processes remains a significant hurdle in semiconductor manufacturing. A well-designed automation infrastructure, built on standardized protocols like GEM and microservice-based architectures, ensures interoperability across generations of test hardware. This allows gradual upgrades while maintaining a unified, disruption-free production environment.

Experience Test and Measurement Software Expertise with Automation for Your Manufacturing Workflows

At Soliton, our mission is to empower semiconductor manufacturers with test automation solutions that seamlessly integrate advanced software, data analytics, and artificial intelligence with manufacturing hardware. Our expertise not only meets the current demands of semiconductor testing but also future-proofs operations as production scales and technology evolve. With our solutions and expertise, we optimize testing processes at every production stage, ensuring consistent quality, improved yields, and faster time-to-market.

Partner with us and experience how our comprehensive expertise in test automation, data, and AI can drive unparalleled efficiency, quality, and scalability in your manufacturing operations.